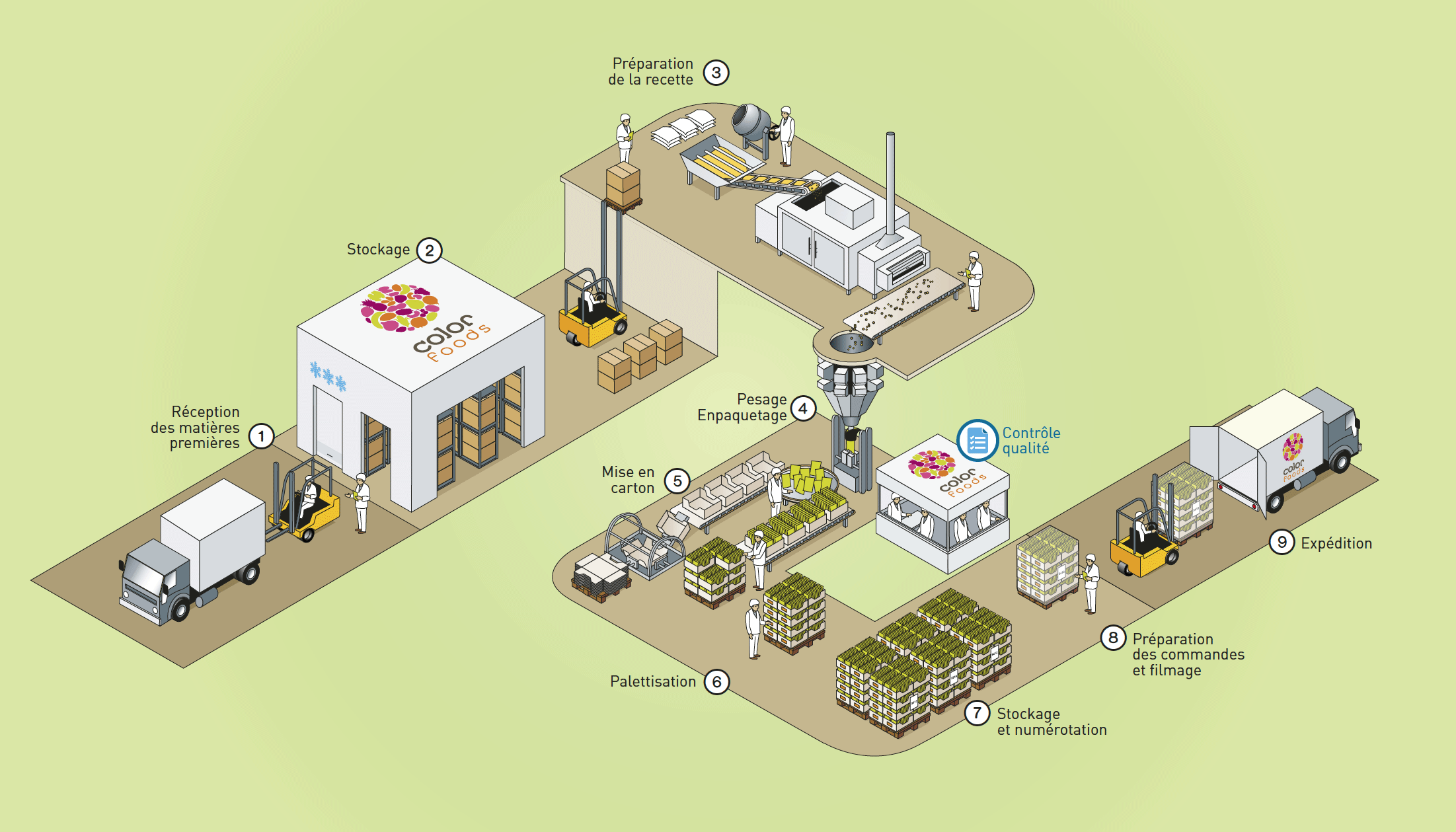

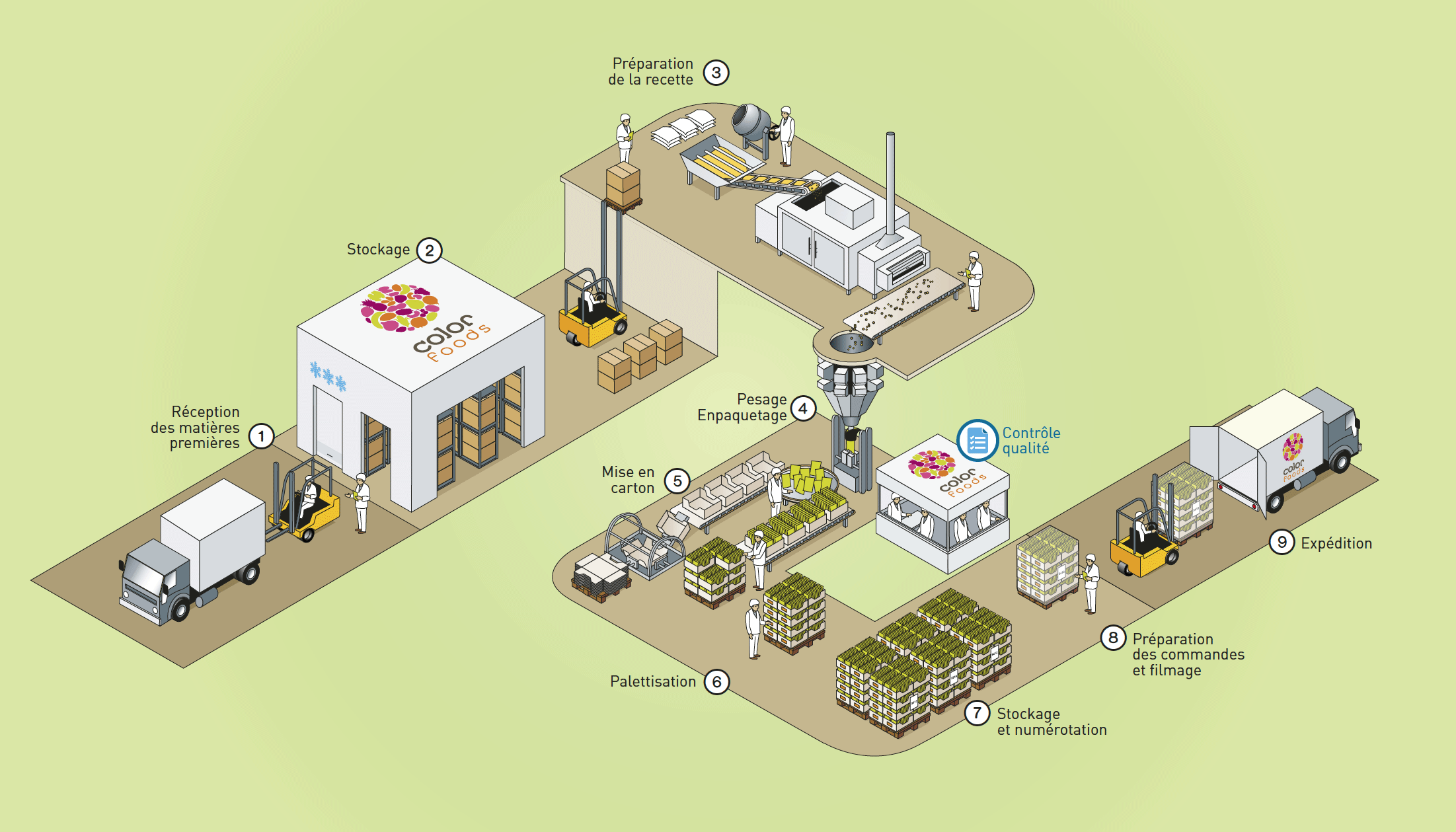

To see details of each stage of our production process at our facility in Marseille, simply place your cursor over the numbers on the diagram.

See behind the details of each stage of our production process at our facility in Marseille.

We carry out quantity and quality checks on all goods at our COLOR FOODS facility on arrival before registering the pallets in our computer system. We then take samples of the raw materials for further checks by our quality department. Only raw materials that pass these checks will be used in the production process.

We carry out quantity and quality checks on all goods at our COLOR FOODS facility on arrival before registering the pallets in our computer system. We then take samples of the raw materials for further checks by our quality department. Only raw materials that pass these checks will be used in the production process.

We have several production lines for preparing our products, where we grill, caramelised, rehydrate, mix or season our dried fruit and nuts:

- SOFT FRUIT: We REHYDRATE dried fruit by spraying it with hot water and/or steam to give it a soft texture.

- CARAMEL-COATED PEANUTS: We CARAMELISE the peanuts in copper tanks, where they’re mixed with sugar and water, which turns into caramel when heated.

- We GRILL cashews, pistachios, peanuts, almonds and hazelnuts in a rotating oven to give them that unique, grilled taste.

- We sometimes SEASON the fruit before roasting, with salt, pepper, spices or herbs.

For more information, visit the “Our processes” page on our SUN brand website.

Fin de réhydratation des abricots

Fabrication des chouchous

grillage des arachides coque

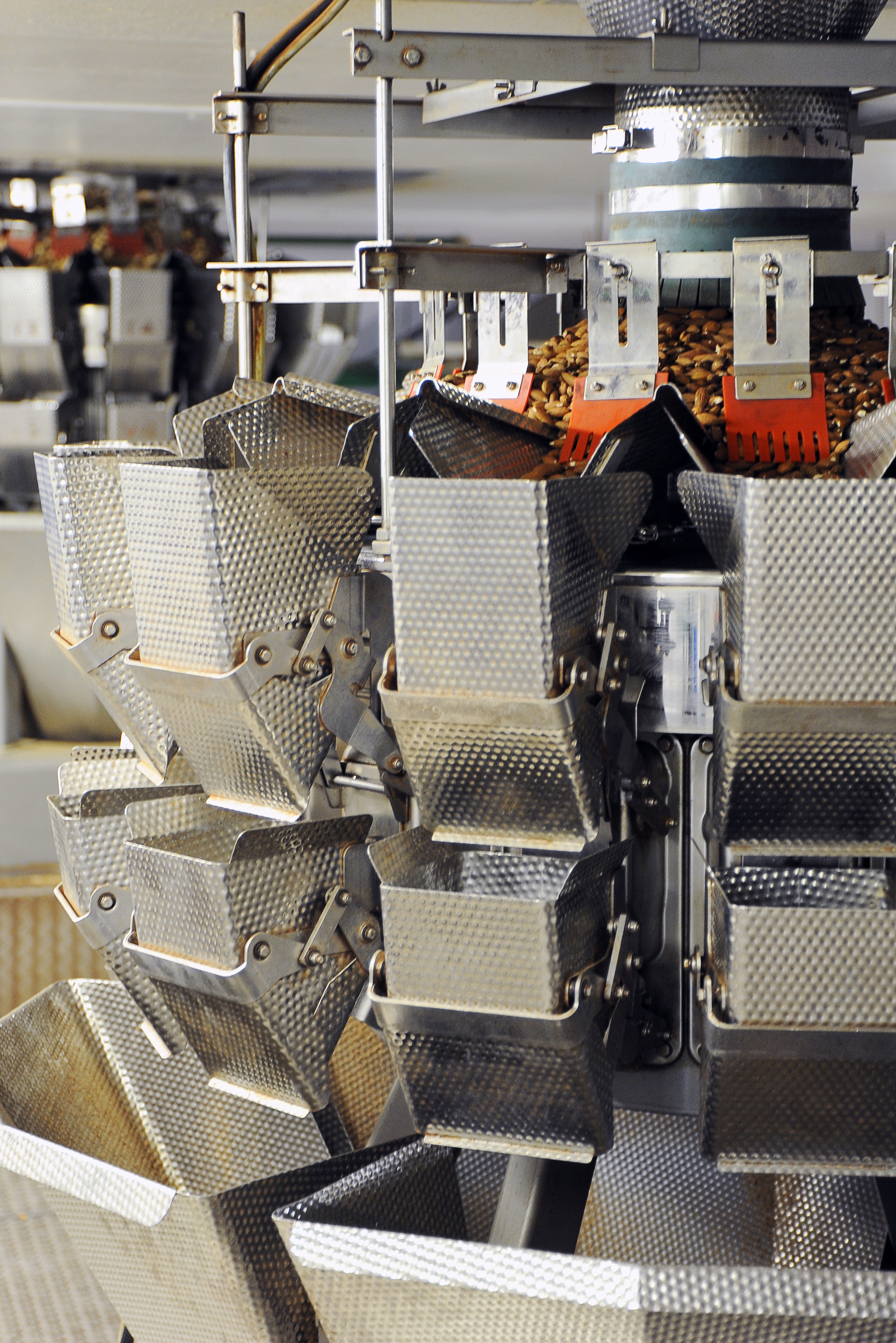

Our packaging lines feature multihead weighers that distribute the fruit into the packs. The products are then ready to be packaged in bags, pots, punnets or boxes, and the end products are then packed in cardboard boxes.

Our packaging lines feature multihead weighers that distribute the fruit into the packs. The products are then ready to be packaged in bags, pots, punnets or boxes, and the end products are then packed in cardboard boxes.

The boxes are then transported to the palletising area, where they are checked before being stored.

The boxes of end products are placed on pallets. Each pallet is identified, numbered and stored. We can store around 2,200 pallets of end products.

We record the origin of all our boxes of products to maintain traceability throughout the logistics chain. We pick boxes according to the First In, First Out (FIFO) rule, to ensure that all the products we deliver to our customers have the longest possible best before date. We also apply the same rule to the way we use our raw materials.

We use barcode scanners to pick and check orders. A second visual check is carried out before the orders are shrink-wrapped and shipped.

The products are then shipped to our customers’ logistics platforms before being transported to stores.

Our quality team’s job is to adhere to our customers’ specifications and the law at all times, and to make sure that our products pose no health risks to consumers.

The team performs multiple checks each and every day with these aims in mind.

We have an on-site laboratory that constantly analyses incoming materials, processes and end products. We perform all analyses that do not require special accreditation. Other analyses are carried out by a specialist independent laboratory.

The first set of checks is carried out when the raw materials arrive. All incoming batches are assessed against our specifications, and we also carry out physical checks (size, weight, quantity, texture, moisture content, etc.) and taste tests. We use accredited external laboratories for additional physical, chemical and microbiological analyses. We also check that all traceability aspects are in place (labelling, identification). Only batches that pass these checks, tests and analyses are released for use on our production lines.

We constantly check that our production processes comply with the relevant recipes, compositions and specifications, and the laboratory performs physical, chemical and taste tests. Additional analyses are carried out by accredited laboratories.

At COLOR FOODS, we’ve been producing soft fruit from dried fruit such as dates, figs, apricots, raisins and prunes since 2005.

Our process involves rehydrating dried fruit by “spraying” it with hot water and/or steam. The water travels around a closed loop. If it is not absorbed by the fruit, it returns back into the tank where it can be used to spray the fruit once again. This process consumes less water and produces less waste than traditional methods using water baths.

The degree of rehydration varies according to the type of fruit and from one harvest to the next. For instance, dates can achieve a maximum moisture content of 26% because they are drier and less permeable. For apricots, the moisture content can be up to 45%.

Dried plums are known as “prunes” if they have a moisture content of up to 35%, or “soft plums” if they take on more water. Raisins take very little time to rehydrate because of their diminutive size.

In short, every type of fruit is unique and we adapt our process accordingly to bring you the very best soft fruit.

Why use hot water?

- Hot water is easier to absorb. Fruit skin, just like your own skin, has pores that dilate when warm to allow water to pass through. When we get hot we sweat because our bodies are around 60% water. But dried fruit has a moisture content of only 18-21%, so the water is actually absorbed into the fruit, turning it “soft”.

- The heat also “pasteurises” the fruit. Pasteurisation is a common food preservation method that destroys the micro-organisms that break down fruit. This means that the fruit continues to taste its best for longer. In addition to pasteurisation, potassium sorbate is often used as a preservative to stop mould and yeast developing.

All cashews, pistachios and peanuts are grilled in our oven. For some recipes, we also grill almonds and hazelnuts.

The difference between grilling and roasting:

- Roasting is a dry, high-temperature process that gives seeds and nuts a trademark flavour. It’s the same process used for coffee.

- Seeds and nuts are grilled to dry them (after seasoning, for instance) or to soften them (e.g. cashews). The process also produces a slight change in flavour, although not to the same extent as roasting.

We use our oven as a dryer. We have a rotating oven with two compartments separated by valves.

Drying fruit involves removing the moisture contained inside. The principle behind it is simple: if the fruit contains more moisture than the air, the water naturally transfers from the fruit to the drier air. Circulating the air through the fruit speeds up the drying process.

We use a two-stage drying process (the fruit passes through two compartments in succession). The air is heated between the two compartments to remove the moisture content before being passed through the fruit again.

PS: We NEVER use fat to grill our nuts.

We make our famous caramel-coated peanuts via a caramelisation process.

We use a traditional recipe based on raw peanuts, sugar and water. The ingredients are mixed together in rotating copper tanks which are heated from underneath.

Step 1: as it heats, the water evaporates and the sugar crystallises around the peanuts as they cook.

Step 2: the temperature continues to rise and the sugar caramelises, coating the peanuts.

Step 3: once the caramelisation process is complete, the tanks tip up and the caramelised peanuts fall onto a conveyor belt, where cold air is passed through to cool them.

PS: We use exactly the same process for the caramelised almonds and hazelnuts in our Douchou TOUFOU mix.

The caramel-coated peanuts are then ready to be packed in our famous cups. Simplicity itself!

Sometimes, we season (with salt and pepper) or flavour (with spices and herbs) our nuts and seeds before roasting them.

For instance, let’s look at how we salt our almonds. The almonds are placed in the mixer, along with water to which we’ve added salt. The water ensures that the seasoning is spread uniformly across the nuts and that it adheres well to the surface. The wet, salted almonds are then placed into the oven. As they dry, the nuts are grilled and the salt crystallises, affixing it to the surface.

We also use a mixer to create our special dried fruit and nut mixes before packaging them, such as our exotic, tropical, crunchy and soft mixes, as well as our Mix Sun Encas products. Yummy!

We have nine packaging lines, each fed by multihead weighers, which dispense exactly the right amount of product into each packaging unit.

We can package our products into plastic bags of different shapes and sizes, as well as into wooden boxes, plastic punnets and even pots.

Our bagging lines also feature protective atmosphere injection systems to keep our fruit at its best for longer.